Blog Layout

Lathes vs Mills: An Overview and Comparison

Feb 05, 2019

Lathes use a rotating workpiece and stationary blade, while a mill uses a stationary workpiece and rotating blade. Together, they’re a powerful and practical presence in any modern machine shop.

Lathes vs Mills: Overview

Lathes use a rotating workpiece and stationary blade, while a mill uses a stationary workpiece and rotating blade. Together, they’re a powerful and practical presence in any modern machine shop.

Lathes vs. Mills: A More In-Depth Look

Lathes and mills are both popular machines to use for shaping metal and other materials with high speed and accuracy, but each plays a very different purpose in the typical machine shop. In fact, while both use sharp, high-strength blades to cut a piece of material—often called a workpiece—and that’s where the similarities end. Let’s take a look at each one and how they differ.

How Do Lathes Work?

There are many varieties of lathes, but they all have the same basic functionality: the workpiece spins, while a stationary blade moves around it, to cut, shape, and create grooves. This setup is ideal for symmetrical, cylindrical items—think table legs, baseball bats, or chess pieces, as a few very basic examples.

Don’t take “stationary” to mean that the blade doesn’t move at all though. In fact, modern CNC lathes will move the blade around the workpiece at many angles to remove material; the blade itself simply doesn’t spin or move in relation to the arm it is attached to.

All About Mills

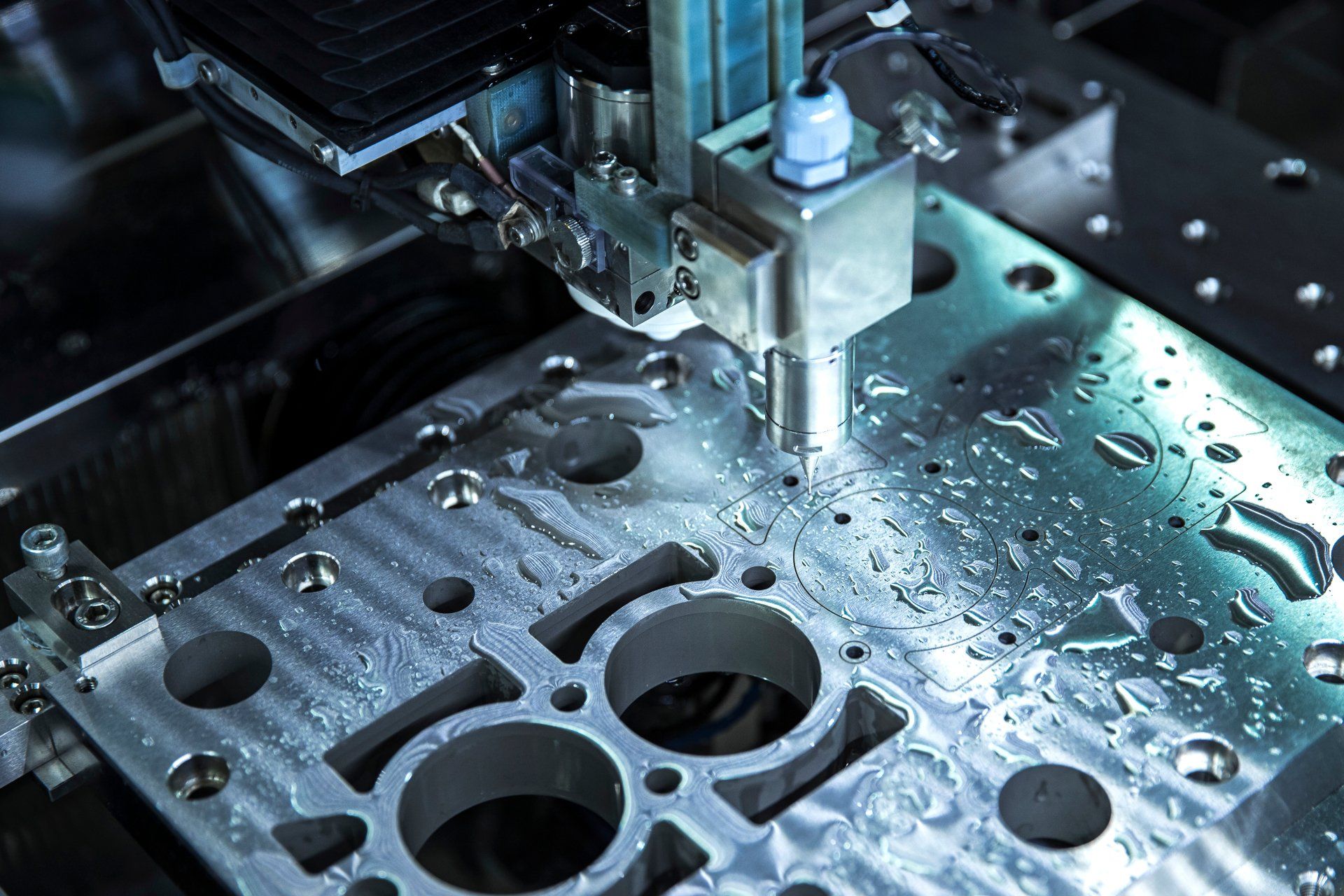

Mills on the other hand, use clamps to ensure the workpiece remains stationary, while the cutting tool rotates at high speed, similar to a drill, and removes material. Mill cutters can have many blades on one cutter, in contrast to a lathe that only uses a single blade. For reference, a standard drill bit typically has one or two blades, but a mill cutter can have two, four or more. Some mills even have multiple cutters on one machine to make cutting jobs go quickly.

Lathes, Mills, and Subtractive Machining

Both tools use what’s called “subtractive machining” which simply means the job starts with a block of material that is cut down to create the ideal shape. This contrasts with additive machining, that uses 3D printing, to add material to an object and create the correct profile. Typically subtractive machining is the quicker option of the two, and both modern mills and lathes can work very rapidly to create prototypes or other machined products

Mills and Lathes: A Complementary Pair

Neither tool is better than the other, and most quality machine shops will have both—sometimes even multiple varieties of each. In general though, lathes are best for cylindrical objects such as shafts or bushings, while a mill is better for drilling, tapping holes, or creating asymmetrical objects. Mills are typically much more flexible, and can be used to create very complex shapes. Each one balances the other’s shortcomings and together they make a powerful pair in any machine shop.

If you’re not sure which would be best for your project, the best bet is to speak with a qualified shop. Just show them your drawings and they’ll help you create accurate prototypes or components quickly and easily.

You might also like

Quick Proto Parts

Quick & Quality

We are available via email or telephone

Location

3727 N Kedzie Ave, Chicago IL

Email

info@quickprotoparts.com

Call

773-463-5026Or Call Toll Free 800-426-6500

© 2024

All Rights Reserved | Quick Proto Parts